Reclaiming water at Danone’s Wevelgem Plant Based Factory, Belgium

Explore moreDanone is a global food and beverage company, with a unique health-oriented product portfolio driven by a mission to bring health through food to as many people as possible. With over 170 production facilities around the world producing dairy, plant-based, water and specialized nutrition products and brands. The Wevelgem site in Belgium produces plant-based foods and drinks under the Alpro brand.

Overview

Thanks to the progressive legislation, considering the long-term sustainability and performance of the plant as well as water availability and autonomy, Danone upgraded the existing wastewater treatment plant and built an additional water reclamation plant with a dedicated distribution network.

This new reclamation plant takes treated effluent that has already passed through biological treatment, clarifier and membrane bioreactor to purify it further. The reclamation unit consists of ultrafiltration, reverse osmosis and chlorination. The treated clean water is reused for different industrial purposes (excluding water as an ingredient). These industrial usages include utilities, cooling towers, sterile barriers and ‘Cleaning In Place’ (CIP).

The treated clean water is reused for different industrial purposes (excluding water as an ingredient). These industrial usages include utilities, cooling towers, sterile barriers and ‘Cleaning In Place’ (CIP).

The water reclamation plant enhances Wevelgem’s operational capability, decoupling growth potential from environmental impact. It reduces overall water usage, and the associated risk of external water shortages. It also unlocks savings by reducing the dependency on external water rates. Through this project, the site reduced its water consumption and enhanced its water autonomy, while maintaining the high-quality standards of products and the potential for additional technical benefits such as recovering heat for power.

The reclaimed water quality output meets all Danone and local requirements including the drinking water quality characteristics. Key parameters such as conductivity, microbiological load or disinfection by-products continue to be monitored regularly.

Key aspects

700

million liters

Wevelgem reclaim unit

produced 700 million liters

reclaimed water from treated wastewater

50%

Plant water intake

reduction of 50%

70%

Water discharge volume reduction of 70%

compared to 2020 prior

to the reclamation project

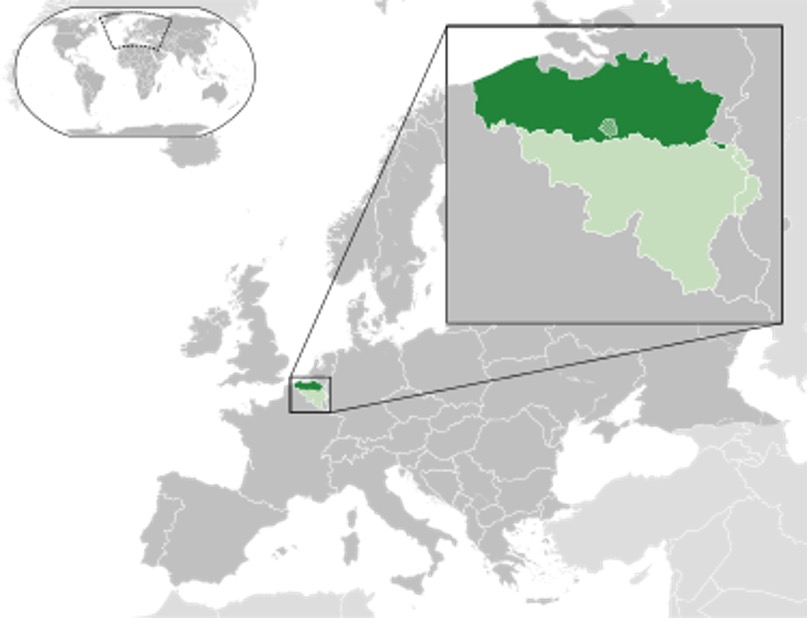

Regional watershed profile

Due to high water stress in the Flanders area of Belgium where the site is situated, authorities embraced regulatory changes to promote water reclamation in industrial practices.

The local authorities allow concentrated discharge of effluent from reclamation systems and the potential to use the treated water as public drinking water.

About Danone’s Wastewater Zero Ambition

Since 2000, Danone has been working to increase water use efficiency and wastewater quality at its production sites.

In 2021, Danone reviewed its internal standards, the Clean Water Standards (CWS) to align with wastewater treatment plants’ capacities and to review against various countries’ regulations. The CWS has strict concentration limits to all wastewater discharges into the local environment, particularly the final discharge of chemical oxygen demand (COD) and net COD ratio that are monitored monthly (see the table below).

Monthly follow up by factor

CWS requirements

| COD (mg/L) | <120 |

| BOD (mg/L) | <40 |

| TN (mg as N/L) | <25 |

| TSS (mg/L) | <50 |

| TP (mg/L) | <2 |

| Oil & Grease (mg/L) | <10 |

| Conductivity (mS/m) | <1000 |

| pH | 5.5 – 9 |

| Temperature (°C) | <40 |

In 2021, 74% of Danone facilities comply with the CWS and by 2030 all factories are committed to be fully compliant with the CWS.

In addition to wastewater discharge, the Danone Water Policy also references important commitments to increase water use efficiency and implement the 4R approach at all Danone production factories by 2030. The 4R strategy being based on projects that Reduce, Reuse, Recycle and finally Reclaim, aiming at reducing water usage inside the plants as a first priority.

Water quality

- The Wevelgem site already had a full Wastewater Treatment Plant with advanced treatment (Membrane Bioreactor) to achieve low levels of solids and organic matter.

- With the implementation of the reclamation system, we reduced the discharge volume improving the overall daily load of pollutants to the local water bodies.

- The discharge reject stream is in compliance with both the discharge permit to local water bodies and the Danone Clean Water Standards, whichever has a ‘stricter’ parameter.

Water availability

- Prior to the project, the discharge from the former wastewater treatment plant averaged around 117m³/h discharged to local water bodies.

- The reclamation plant allows to consistently produce safe treated water to the required reuse quality: according to Belgian law and Danone internal standards.

- The reclamation plant unit has an initial capacity of 82 m3/hr (720,000 m3/year), which can later be scaled up to 106m3/hr (930,000 m3/year).

In 2022, the Wevelgem reclamation plant has produced 700 million liters of reclaimed water from treated wastewater, enabling a plant water intake reduction of 50% and a water discharge volume reduction of 70% compared to 2020 prior to the project.

GHG impact of wastewater management

At Danone group level, each site monitors key environmental metrics relating to water, waste and energy including GHG at a monthly basis via an internal tool called ‘Greentrack’ which is audited annually.

Internal programs and targets are monitored, and best practice communities share reduction initiatives and learnings.

The water reclamation process had a neutral impact on GHG emissions (no reduction or increase) whilst reducing water usage.

Key lessons learned on the “Wastewater Zero” journey

- Supportive local regulations.

- Risk of increase on the price of water and the water scarcity situation.

- ‘Build to operate’ mindset; co-build the construction of the site with a contractor who can also operate the site in practice.

- Maintain robust internal specifications for water quality which allows clear alignment with suppliers.

- Ensure positive financial impact embedded within project KPIs.

Copyright © 2024

World Business Council for Sustainable Development

All rights reserved | Privacy Policy